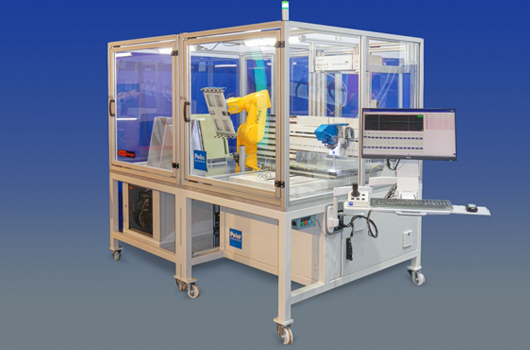

The DVS550 is an automated prober for measurements replacing the previously time-consuming procedure carried out manually. A highly flexible, low loss coaxial cable feeds the signal at the probe tip to a variety of test and measurement equipment such as High-Speed Oscilloscopes, Spectrum Analyzers or Time Domain Reflectometers. It has options to control external hardware via USB, Ethernet, GPIB, RS232.

The DVS550 can test and document measurements on hundreds of nets in less than a few hours while manual measurements would take weeks of valuable engineering time. The DVS550 System has been designed for measuring signal frequencies into the GHz range using custom designed coaxial probing technology contrasting significantly conventional Flying Probe Systems with a focus on detecting typical manufacturing faults.