Atlas for Anritsu VNA is compliant with IPC TM650 2.5.5.12 (Test Methods to determine the Amount of Signal Loss on Printed Boards) and provides support for Delta-L methodology.

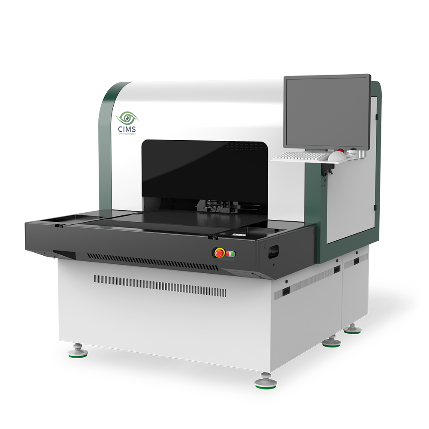

Atlas Si is a high precision insertion loss measurement package designed specifically for PCB fabricators and OEMs. It provides accurate, repeatable measurements of frequency-based transmission line losses, allowing fabricators to meet stringent targets that maintain signal integrity within the limits of the latest high-speed chipsets.

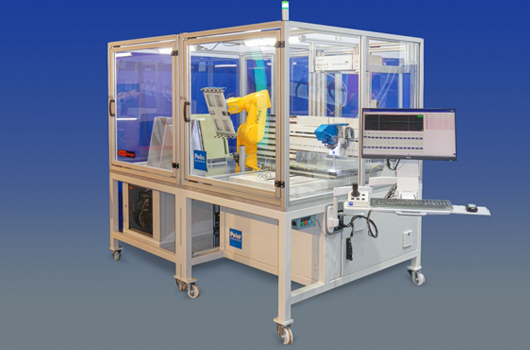

Polar has partnered Anritsu for integrating their Anritsu ShockLine™ 4-Port Performance VNA (vector network analyzers) with Atlas. Anritsu ShockLine™ 4-Port Performance VNAs achieve a new level of capability, flexibility, and value for RF and microwave network analysis applications delivering excellent performance for measurements from 50 kHz up to 43.5 GHz. These instruments are ideal for testing passive and many active components with general purpose VNA requirements. The ShockLine family employs advanced Anritsu technology and design expertise to attain outstanding dynamic range, calibration and measurement stability, and speed performance in efficiently packaged, compact, and robust VNA instruments.

Anritsu ShockLine™ 4-Port Performance VNA Key Features and Benefits

- Time domain with time gating option enables easier and faster fault identification in broadband devices

- Patented non-linear transmission line (NLTL) technology delivers wider bandwidth and higher dynamic range than competing technologies, enabling better measurement accuracy and repeatability with longer intervals between calibrations

- Multiple calibration methods to choose from to best suit your application – SOLT, SOLR, SSLT, SSST, LRL, LRM, or Thru update

- Precision AutoCal™ or SmartCal™ for an easy, one-button automatic method of VNA calibration

- Eliminates the need for over-specified, high-end VNAs with extra features not required for production testing

- Anritsu’s Extended-KTM connectors enable ShockLine frequency option 43 VNAs to offer guaranteed performance to 43.5 GHz in a K/2.92 mm compatible form factor

Download Brochure

Note: Anritsu Corp., USA are the sole owners of following trade marks for ShockLine™, AutoCal™, SmartCal™ and Extended-KTM