Kitagawa Seiki, Japan is a leading supplier of proprietary thermal, pressure, control and other advanced technologies vacuum press to develop and manufacture innovative, high-performance, high-quality PCB and CCL products.

Kitagawa develops and manufactures press-related machinery for a wide range of applications including copper clad laminates, fabrication of printed circuit boards for use in mobile communications, home appliances, car electronics, and satellites. By developing and designing machinery and control systems to meet specific customer needs, we are helping to improve production efficiency.

PCB Pressing Equipment

PCB Pressing Equipment

CCL press Equipment

CCL press Equipment

| Vacuum Press for Making PCBs(FPCs) | |

| Press Capacity | 104kN ~ 4490kN (11ton~458 ton) |

| Effective Area | 720X1260 mm |

| Number of openings | 10 or asper the customer spec |

| Max usable temp | 260°C |

| Heating Method | Thermal oil circulation with Heater |

| Strength of vacuum attained | 1.3kPa(10 tar) |

| Peripheral equipment | Automated loader (5-unit capacity) and PC |

- Customised specifications to meet specific customer needs.

- Presses are subject to minimal age-related deterioration, ensuring consistent high-quality products over its life cycle.

- Proprietary technology minimizes strain, enabling production of higher quality products.

- No. 1 global market share for large vacuum presses for making CCL.

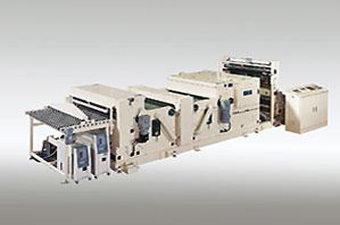

Prepreg Cutting System

- Kitagawa Seiki's proprietary cutting technology reduces the flying of resin chips and prevents breakage of resin edges.

- Minimal possibility of damage due to cutting dust being carried over to the next process.

- Installation of an optional surface inspection unit enables detection of prepreg defects

| Prepreg Cutting Machine | |

| Cutting system | Longitudinal Cutting: Slitting Lateral Cutting: Shearing |

| Max PP size | Sheet material: Max. diameter: 550 mm Max. width: 1,270 mm Paper tube: |

| Cutting Size | Longitudinal cutting: 300 to 1,270 mm (maximum 4 sections) Lateral cutting: 350 to 2,500 mm (length) |

| Max Processing capacity | 30 m/minute (for lateral cutting length of 2,500 mm) |