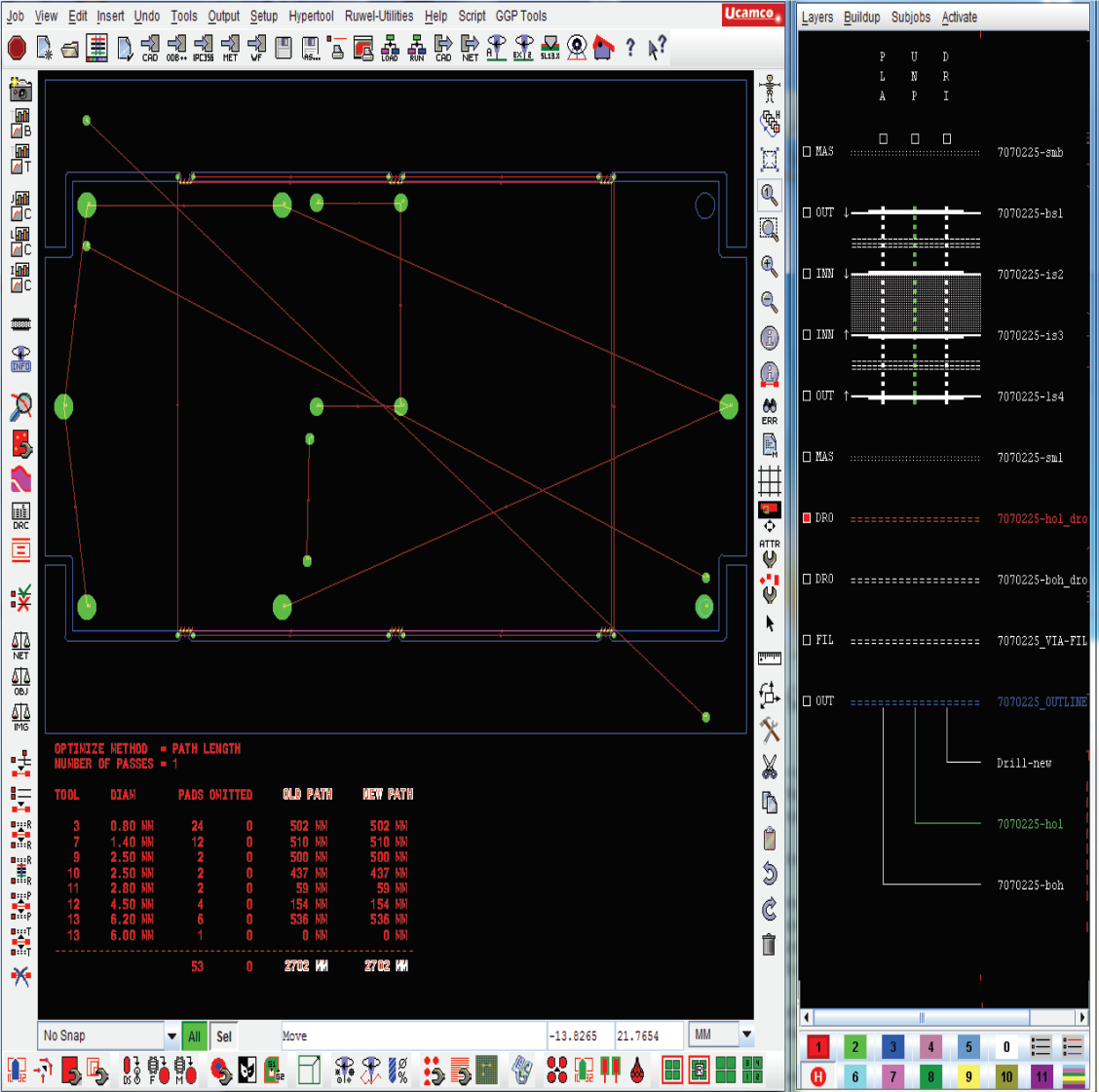

UcamX Pro+ is Ucamco’s latest generation of CAM software for the Rigid, Flex and HDI PCB manufacturing industries. It takes advantage of modern-day multicore and 64 bit workstation technology to set new standards in performance and throughput, and comes with a clever and highly intuitive new user interface that adapts itself functionality-wise as a job progresses through the CAM workflow.

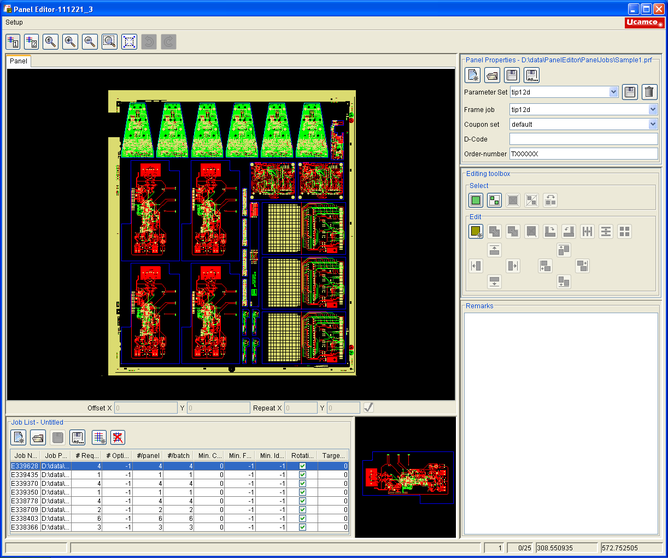

It captures not just layout data but also netlist information, customer specifications, mechanical drawings and manufacturing rules in a single smart engineering database. UcamX Pro+ deploys powerful automatic security tools to detect accidental operator errors. UCamX Pro+ outputs fully-automated machine-optimized tooling for all industry-standard electrical testers and AOI systems, photo plotters, drilling and routing equipment and direct imagers. It is delivered ready-automated with built-in dynamic functionality for a fast roll-out and a fully customized smart workflow. Labor-saving functions include automated board structuring, netlist and test-point generation without manual intervention, & dynamic yield-driven auto-panelization.

Main Features

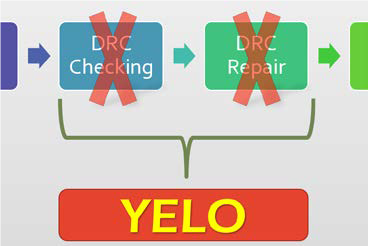

- YELO Automatic DfM Adjuster

- Tombstone and Solder Escape Prevention

- Secure Etch Compensation with Horns

- 64 Bit, Multi-Core Parallel Processing

- Zero-defect tooling

- Out-of-the-box CAM productivity

- 100% integration into existing environment

- State-of-the-art intuitive user interface

- Wait times on complex algorithms slashed by up to 500% (8-core)

- Top-notch performance by using parallel processing on today’s multicore processors

- High-level automation – without limits

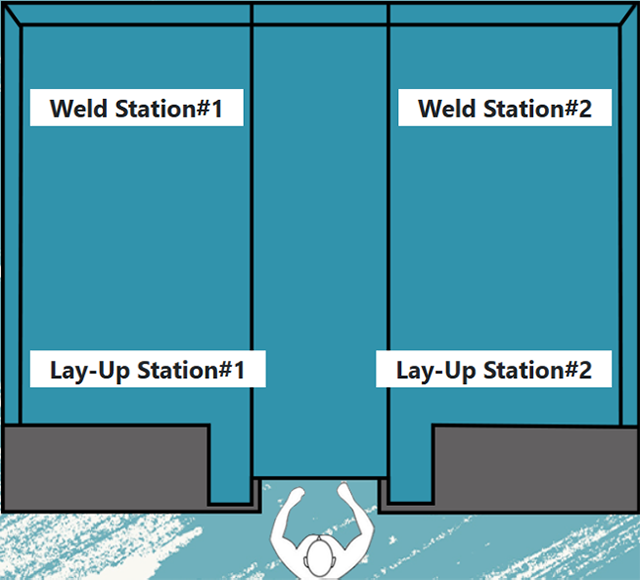

PCB Pressing Equipment

PCB Pressing Equipment

CCL press Equipment

CCL press Equipment