The Colenta NG - PCB Film Processor is a fully automatic “dry to dry” processing system designed to provide consistent high-quality film production for the range of PCB films commonly used in the industry. The processor design incorporates a non-opposed, submersed roller transport system with minimal contact to the film emulsion and with intermediate wash water crossovers that safely transfer the film between each stage of processing before delivery onto a flat receiving tray located at the exit of the dryer.

Range of PCB Processor available:

Wide Track PCB Processor range, offering 140 and 200 cm processing width.

Processing capacity: 80cm / min processing capacity @ 40 sec Dev Time.

The NG Processor is available in 35, 56, 66, 80, 95 and 110cm process widths.

Available in NG and NGs formats that offer a choice of production speeds: -

- NG: 82cm / min processing capacity@ 30 sec Dev Time

- NGs: 115cm / min processing capacity@30 sec Dev Time

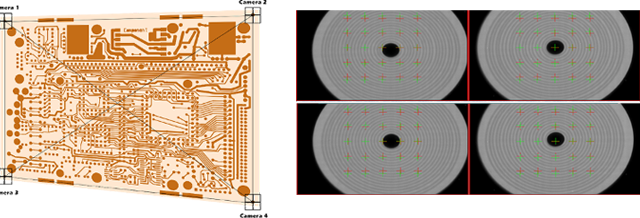

In Offline (manual loading table) or online format (auto loading) to support all major PCB Film Plotters available on the market.

Accesories

COLENTAMC Chemical mixing, transfer & storage console

The MC is a multipurpose semi-automatic device for accurately mixing chemical concentrates with water, for transferring mixed chemistry into the processor tanks and to store replenishment solutions that connect directly to the processor replenishment pumps without the need for additional storage tanks.

COLENTA Silver recovery system Silverfit 40

An automated system used to recover silver from the waste Fixer solution before disposal or re-use, suitable for NDT, PCB and Medical Imaging applications.

COLENTA Easy Clean cleaning products

A specialized range of liquids designed to help operators keep their processor clean and in good operating condition.

COLENTA water panel assembly

Including filter, flow meter, thermometer and pressure gauge. Supporting 2 water outlets, one to be used for supplying wash/cooling water to the processor and one additional outlet for use during service, cleaning and chemical mixing procedures.

COLENTA PC monitoring software

When installed onto a PC, will allow the processor status and working parameters to be monitored remotely.

Download NG Processor Brochure

Download NG Processor Datasheet

Download Wide Track PCB Processor Brochure

Download Wide Track PCB Processor Datasheet

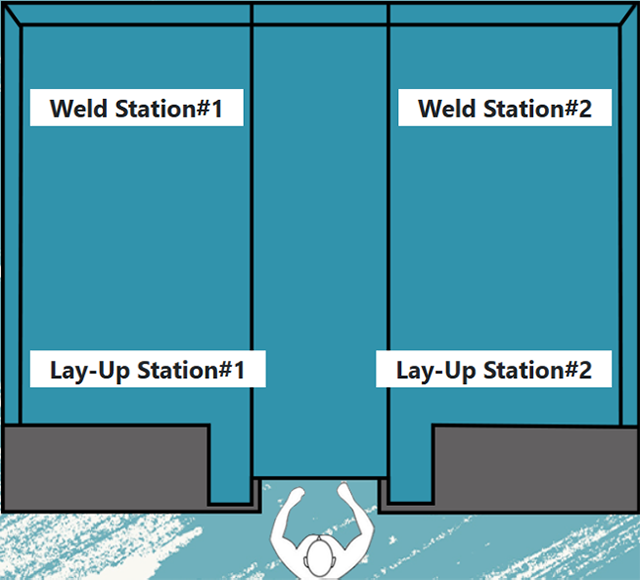

PCB Pressing Equipment

PCB Pressing Equipment

CCL press Equipment

CCL press Equipment