Kitagawa Seiki,日本是專有的熱,壓力,控制與其他真空壓合先進技術開發和製造創新的,高性能,高品質的PCB和CCL產品的領先供應商。

Kitagawa Seiki開發和生產壓合相關機械的廣泛應用,包括覆銅板壓合,印刷電路板在移動通訊,家電,汽車電子,衛星使用的製造。通過開發和設計的機械和控制系統以滿足特定客戶的需求,我們正在幫助提高生產效率。

PCB Pressing Equipment

CCL press Equipment

| Vacuum Press for Making PCBs(FPCs) | |

| Press Capacity | 104kN ~ 4490kN (11ton~458 ton) |

| Effective Area | 720X1260 mm |

| Number of openings | 10 or asper the customer spec |

| Max usable temp | 260°C |

| Heating Method | Thermal oil circulation with Heater |

| Strength of vacuum attained | 1.3kPa(10 tar) |

| Peripheral equipment | Automated loader (5-unit capacity) and PC |

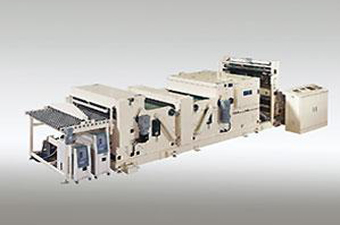

Prepreg切割系統

| Prepreg Cutting Machine | |

| Cutting system | Longitudinal Cutting: Slitting Lateral Cutting: Shearing |

| Max PP size | Sheet material: Max. diameter: 550 mm Max. width: 1,270 mm Paper tube: |

| Cutting Size | Longitudinal cutting: 300 to 1,270 mm (maximum 4 sections) Lateral cutting: 350 to 2,500 mm (length) |

| Max Processing capacity | 30 m/minute (for lateral cutting length of 2,500 mm) |